Computational Fluid Dynamics (CFD) modelling is a powerful tool for designing and optimizing hydraulic systems, leading to improved performance, efficiency, and reliability. When designing hydraulic systems, CFD modelling offers several key benefits:

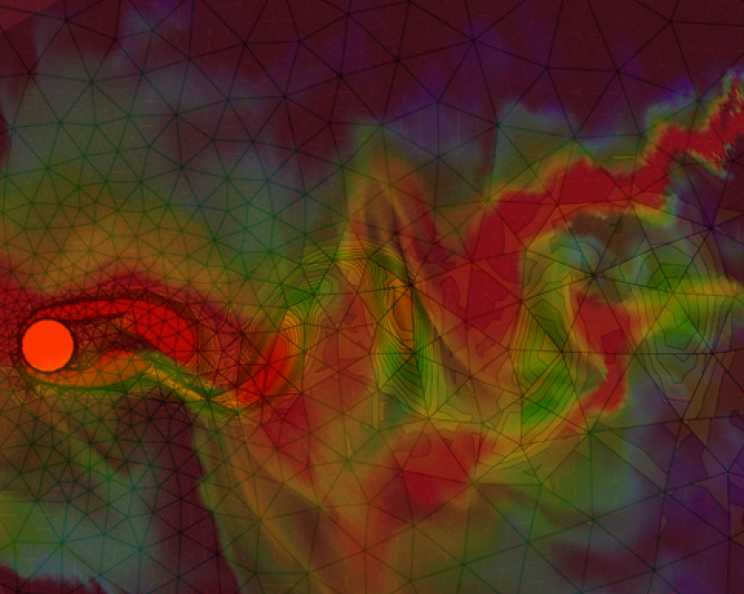

- Flow Analysis: CFD can simulate the flow of hydraulic fluid through the system, providing insights into flow patterns, velocities, and pressures. This helps engineers optimize the design for efficient fluid flow.

- Pressure Analysis: CFD can predict pressure distribution throughout the hydraulic system, aiding in the design of pumps, valves, and other components to ensure adequate pressure levels.

- Optimization of Component Design: CFD can optimize the design of hydraulic components, such as valves, pipes, and fittings, to minimize pressure losses, reduce energy consumption, and improve overall system performance.

- Cavitation Analysis: CFD can predict the occurrence of cavitation in hydraulic systems, which can lead to component damage and reduced system efficiency. This allows engineers to design measures to mitigate cavitation effects.

- Temperature Analysis: CFD can simulate the thermal behaviour of hydraulic systems, helping engineers ensure that components are properly cooled and that the system operates within safe temperature limits.

- Noise Reduction: CFD can be used to study and reduce the noise generated by hydraulic systems, optimizing component design and operating conditions to minimize noise levels.

- Environmental Impact Assessment: CFD can assess the environmental impact of hydraulic systems, such as the dispersion of hydraulic fluids or the impact on aquatic ecosystems, aiding in environmental impact assessments and mitigation planning.

Contact details:

Contact details: